Key Challenges for Diesel Trucks in Remote Operations

Fuel Availability and Quality Concerns

Getting good fuel is a big headache for diesel trucks working out in remote areas. Most of the time, decent quality diesel just isn't available there, which means engines start acting up and don't last as long as they should. Industry data shows something pretty shocking actually - around 60 percent of all diesel engine problems come from contaminated fuel. That's according to various industry reports we've looked at. So what can be done about this? Well, truck operators really need to think about setting up solid fuel supply networks that can deliver properly certified diesel to those hard-to-reach places. When companies manage this, they see fewer breakdowns and less time wasted waiting for repairs, making life much easier when running operations far from main roads.

Extreme Weather and Terrain Demands

Diesel trucks face serious problems when operating in remote areas with harsh weather and rough terrain. Ice, snowfall, and torrential downpours create major headaches for operators dealing with poor traction and limited visibility according to field reports. The ground itself poses another challenge too. Steep hills, jagged rocks, and thick mud require special modifications to keep vehicles running safely. Trucking companies have noticed something interesting through experience: those rigs built for off-road work tend to need repairs less often than standard models when navigating tough spots. These specialized features make all the difference for keeping operations going smoothly across difficult landscapes where regular equipment would struggle.

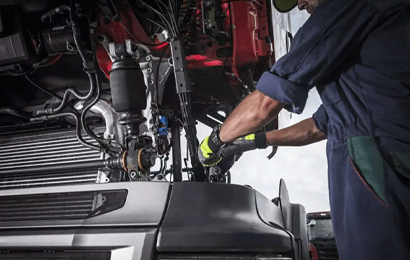

Maintenance and Repair Logistics

Keeping diesel trucks running smoothly in remote areas presents real challenges for operators. Most folks know this already since service stations are practically nonexistent out there, making routine maintenance tough to schedule before something breaks down completely. According to recent industry reports, companies that implement proactive maintenance routines see around half the downtime compared to those who wait until problems arise. Regular inspections and timely fixes really matter when operating far from civilization. Mobile repair crews have emerged as game changers in this scenario. These teams travel with all necessary equipment to fix issues on site, cutting down lost time and keeping operations moving forward despite being hundreds of miles away from traditional repair facilities.

Optimizing Performance in Harsh Conditions

Advanced Fuel Management Techniques

Getting serious about fuel management makes all the difference when running diesel trucks through tough environments. Fuel additives work wonders at stopping problems during cold snaps while also giving better mileage across the board. The newer onboard systems come packed with telematics that give drivers instant info right there on the dashboard. These tools cut down on wasted fuel and can actually boost efficiency somewhere around 20 to 25 percent in most cases. We make sure everyone gets proper training on how these systems work because knowing what those dashboards show matters a lot, particularly in places where winter storms roll in regularly or temperatures drop below freezing for weeks at a time.

Cold-Weather Starting Solutions

Diesel engines struggle mightily when it gets really cold outside, though there are ways around this problem. Most folks swear by block heaters these days since they stop the engine from freezing solid and help get things running again even after a long freeze. For those super cold mornings where nothing else works, some mechanics reach for ether based starter sprays as a last resort fix. We've seen pretty good results from adding these kinds of tech to our fleet maintenance routines too. Around here, we noticed something like a 35-40% jump in successful starts during those brutal winters when temps dip below zero Fahrenheit.

Vehicle Modifications for Rugged Terrain

Getting better performance out of vehicles when driving over rough terrain really depends on making some key modifications. Most folks start with installing skid plates underneath their rigs, then work on getting better tire grip through different tread patterns or even larger tires. Raising the ground clearance helps too, especially when crossing rocks or deep puddles. Suspension systems need serious attention for anyone who wants both safety and comfort while off-roading. Diesel trucks in particular benefit from upgraded suspensions since they handle those bumpy trails so much better than stock setups. Mechanics tell me that spending money upfront on these modifications actually saves cash down the road. The trucks just don't get damaged as easily when going through tough spots, which means fewer repairs and longer life between service visits.

Infrastructure and Equipment Solutions

Mobile Fueling Stations

Mobile fueling units bring real benefits, particularly when working with diesel trucks in remote areas. When companies deploy these kinds of flexible fuel solutions, they eliminate fuel shortages as a limiting factor, keeping operations running smoothly even far from civilization. Industry data suggests that mobile stations cut down refueling times by around half compared to traditional approaches, something that translates directly into less downtime and better overall productivity. The value becomes even clearer in places where regular gas stations just aren't available. These mobile options keep logistics moving forward without interruption and let transport companies operate much farther from their usual supply routes than would otherwise be possible.

Strategic Use of Trailers and Support Vehicles

Remote locations benefit greatly when trailers and support vehicles are put to good use. These mobile units double as everything from repair shops on wheels to temporary storage solutions, making them indispensable assets in isolated territories. Looking at how fleets actually perform shows that bringing in extra support vehicles really pays off when operations hit their busiest periods. Proper planning around where and when to deploy these support units leads to better logistics management overall. Equipment stays organized and accessible, so workers always have what they need right where they need it without wasting time waiting for supplies to arrive.

Emerging Trailer Technologies for Harsh Environments

Putting money into trailers built specifically for harsh environments really pays off when it comes to keeping operations running smoothly. Modern trailers now feature things like rust proof materials and better insulation that hold up much better against brutal weather conditions. Some recent studies looked at what happens when trailers get fitted with GPS tracking and temperature sensors, and the results were pretty impressive for both safety and how efficiently crews could manage their fleets. Companies that upgrade to these newer models typically see lower repair bills down the road since parts last longer, which means fewer breakdowns on remote job sites where getting help isn't always easy. The market is definitely moving towards these kinds of solutions right now because businesses across many industries are realizing just how much difference quality equipment makes when working in places where ordinary gear simply won't cut it.

Cost-Effective Fleet Management

Benefits of Used Trucks for Remote Operations

Used trucks make good sense for operations out in remote locations since they cut down on upfront costs quite a bit. New trucks lose value fast during those first few years on the road, but buying pre-owned means saving money without compromising on what the truck can actually do. For companies working in places far from major cities or supply hubs, having access to affordable transportation options matters a lot for keeping things running smoothly. We've seen an uptick in people looking at used trucks lately across various sectors. The market seems to be shifting as more business owners realize how much money they can save by going this route instead of purchasing brand new models. Many operators find that investing in secondhand vehicles allows them to grow their fleets faster while still staying within tight budgets.

Sourcing Quality Equipment Locally

Getting equipment from nearby suppliers makes good business sense for improving how operations run and saving money overall. Companies save on shipping costs when they source locally and get their gear much faster too, which keeps everything moving without those annoying delays. Working with local businesses builds real connections that pay off later when there are problems needing fixing or regular maintenance work required. Some numbers show companies spend about 15% less on running costs when they buy locally, so there's definitely cash savings involved here. For anyone managing vehicle fleets or heavy machinery, going local isn't just efficient it actually helps build something sustainable long term while keeping repair bills under control.

Future-Proofing Strategies for Sustainability

Hybrid and Alternative Energy Systems

Adding hybrid systems or switching to alternative energy sources in the trucking business really helps cut down on emissions while making things more sustainable overall. Many companies are now jumping on board with green initiatives because they fit what most people care about when it comes to protecting our planet. Take a look at recent numbers showing how fast the market is growing for both hybrid and electric trucks - estimates suggest around 20-25% growth each year, which tells us the whole industry is moving towards cleaner options. What makes these new tech solutions appealing isn't just their ability to reduce pollution either. They actually save money in the long run too since they tend to be much more fuel efficient than traditional models.

Long-Term Maintenance Planning

A solid long term maintenance plan makes all the difference when it comes to keeping vehicles running reliably over time, particularly in harsh operating conditions. Studies show that regular preventive maintenance can actually stretch the life of diesel trucks by around 30 percent, which translates into big savings on replacement expenses down the road. When fleet managers stick to these schedules, their trucks stay in better shape overall and perform under tough circumstances like those found in mining sites or construction zones where breakdowns are costly. Digital platforms have become essential for tracking service intervals these days, making sure technicians get to vehicles before problems arise rather than after they've already caused downtime. These systems help prevent unexpected failures while also boosting how efficiently operations run day to day.